In modern industrial environments, material performance and durability are critical factors that influence operational efficiency and safety. Pultruded FRP grating has emerged as a popular choice for many industries due to its superior strength, corrosion resistance, and lightweight properties. However, selecting the right pultruded FRP grating to meet specific industrial needs requires a careful understanding of its characteristics, applications, and installation considerations. This article explores key factors to consider when choosing pultruded FRP grating for industrial use.

Understanding Pultruded FRP Grating

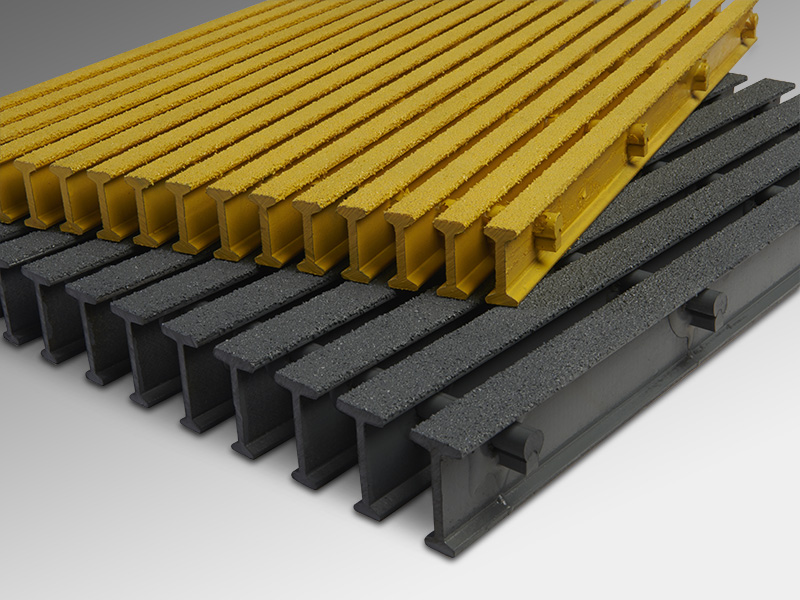

Pultruded FRP grating is a composite material fabricated through the pultrusion process, where continuous fiberglass strands are saturated with resin and pulled through a heated die to form strong, durable profiles. This grating is widely used in industrial settings for platforms, walkways, stair treads, and trench covers because of its ability to withstand harsh environmental conditions. Unlike traditional metal gratings, pultruded FRP grating offers excellent resistance to corrosion, chemicals, and moisture, making it particularly suitable for industries such as chemical processing, wastewater treatment, marine, and food processing.

Key Performance Characteristics

When considering pultruded FRP grating, it is essential to evaluate the mechanical and chemical properties that will impact its performance in the intended application. The tensile and flexural strength of pultruded FRP grating is typically higher than molded FRP options, offering enhanced load-bearing capacity. Its non-conductive nature provides safety advantages in electrical environments. Furthermore, the grating’s slip resistance can be optimized through surface treatments, which is vital for workplace safety, especially in wet or oily conditions.

Assessing Environmental and Chemical Exposure

One of the primary reasons industries choose pultruded FRP grating is its resilience against environmental challenges. However, different industrial environments may expose the grating to a variety of chemicals, UV radiation, temperature extremes, and moisture levels. It is important to select a resin system compatible with the specific chemicals and temperature ranges present in the application. For instance, vinyl ester resins offer superior chemical resistance compared to polyester resins and are recommended for environments with aggressive chemicals. Additionally, UV-resistant coatings can be applied to protect the grating from prolonged sun exposure and prevent degradation.

Load and Span Requirements

Industrial applications often require gratings to support heavy loads while spanning considerable distances between supports. Properly matching the load-bearing capacity and maximum span of the pultruded FRP grating to the structural design is critical to ensure safety and longevity. Load tables provided by manufacturers detail the allowable loads for various thicknesses and grid sizes of grating. It is advisable to work closely with structural engineers and suppliers to determine the appropriate grating specifications that align with operational demands, considering factors such as dynamic loads, point loads, and safety margins.

Installation and Maintenance Considerations

Pultruded FRP grating is favored not only for its durability but also for its ease of installation and low maintenance requirements. Compared to steel gratings, it is significantly lighter, which reduces labor and handling costs during installation. The corrosion-resistant properties mean that the grating requires minimal upkeep, eliminating the need for frequent painting or protective coatings. However, proper installation techniques are essential to avoid issues such as grating movement or improper load transfer. Utilizing compatible fasteners and support structures designed for FRP materials will enhance system performance and safety.

Cost Efficiency Over Time

While the initial investment in pultruded FRP grating may be higher than traditional materials, its long-term cost efficiency often justifies the expense. The grating’s resistance to corrosion and chemicals reduces replacement frequency and downtime caused by maintenance or failure. Additionally, the lightweight nature decreases transportation and installation expenses. Evaluating the total lifecycle cost, including installation, maintenance, and replacement, helps in making an informed decision that aligns with both budget constraints and operational goals.

Conclusion

Choosing the right pultruded FRP grating for industrial applications involves a comprehensive evaluation of material properties, environmental conditions, load requirements, and maintenance expectations. By understanding these factors, industries can leverage the unique advantages of pultruded FRP grating to enhance safety, durability, and cost-effectiveness in demanding environments. Collaborating with knowledgeable suppliers and engineering experts further ensures that the selected grating solution meets the precise needs of your industrial operation, providing reliable performance for years to come.